Safety & Health

We, under its human-oriented

management, prioritize

the well-being of

all employees and stakeholders

in every business decision making process

Systematic Safety & Health management

LG group affiliates identify potential hazard in their main production sites through the safety & health management system (ISO45001). LG Display, under its integrated safety management system, observes all legal regulations and implements efficient safety measures.

LG Display’s integrated safety management system

| Item | Main functions | |

|---|---|---|

| Safety & Health Information | Provide information such as safety standards and guidelines | |

| Safety Work Management |

Work permit status, hazardous work information, risk assessment DB, safety officer certification | |

| Safety Culture | Safety Talk manual provision, employee recognition |

|

| Smart Safety Suggestions |

Request for improvement in unsafe practices, suggestion for safety related issues | |

| Records of accidents/ statistics | Manage accident reports and analysis, accident trends and statistics | |

| Training Management | Establish safety & emergency training plan and check progress status | |

| Chemical Substances | Provide data, such as MSDS and current information on chemical materials in use. | |

| Protective Gear Management | Purchase protective gear, manage payment history. | |

| Legal Activity Management |

PSM (Process Safety Management), hazardous machinery and materials safety management |

Preemptive risk identification and response

LG Chem identifies potential danger factors in advance through frequent inspections on business sites based on its safety priority. In addition, it prevents any occurrence of hazards in high-risk work with double and triple safety measures.

LG Chem’s preemptive risk identification of

and response process

- Change occurs

-

Grade classified

- Establish regular assessment plan

- Conduct risk assessment (on process/work)

-

Committee review necessary?

- N

- Request for change review (on process/work)

- Change reviewed/ approved (Change Management Committee)

- Change reflected (Commence work)

- Pre-operation check

- Hold committee meeting (regular/irregular) : Change requires review

- Committee review report release * E-approval report with final feedback reflected

-

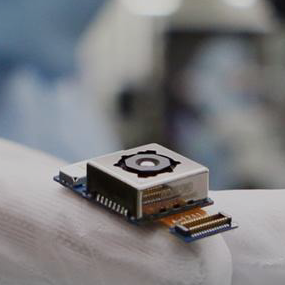

Automation and Robotics for Safe Work Environment

LG Electronics utilizes AI robots in high-risk tasks for safety and efficiency. As the robots undertake dangerous and meticulous tasks, the workers can focus more on monitoring and controlling the overall production line performance. -

Safety and Health Support Solution Development

LG U+ plans to make the workplace safe and constructive for workers by launching a) Safety Management DX Service (an integrated safety & health management platform), b) IoT/AI based smart safety equipment, and c) intelligent video security solution. -

Safety Day

LG Innotek increases safety awareness through identifying potential risk in each production process and promoting idea generation for improvement.