LG Chem LUCON® TX5007, the engineering plastic used for electrostatic powder coating is now applied to Japanese global OEM’s Front Fenders

2023.01.10LG Chem has started supplying engineering plastics to Mitsubishi Motors for its powder coating parts used as the front fenders of RVR, Delica D:5 and Outlander models.

Front fender is located on the side of the vehicles, which not only acts as one of key factors in the exterior design but also protects its wheels from road debris. Thus, it not only should possess a high level of mechanical robustness but also an excellent exterior quality to keep a high integrity design with the rest of the car body.

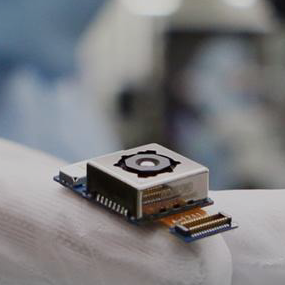

LUCON TX5007 developed by LG Chem is a compound material that combines modified polyphenylene ether (mPPE) and polyamide (PA66) alloy with carbon nanotubes (CNTs), and has an excellent electrical conductivity and show strong mechanical properties. In addition, this product has an outstanding heat resistance, making it suitable for the automotive on-the-line painting process at 200 °C or higher. At the same time, it also provides an excellent dimensional stability thanks to its low coefficient of linear thermal expansion (CLTE).

In general, applying plastics instead of steel/aluminum contributes to automotive light weight. When a plastic fender is used, the weight of the vehicle is reduced by about 4 kg, which also improves fuel efficiency. Furthermore, plastic fenders can provide other benefits, such as reduced fuel exhaust emissions and carbon footprints.

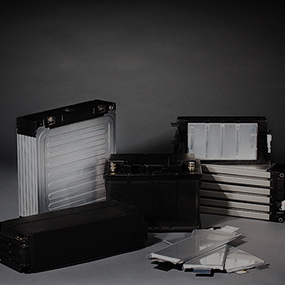

In addition to LUCON TX5007, LG Chem has a broad portfolio of products that can be used for large-scale automotive exterior parts that need to utilize powder coating process. These products can be customized to meet automotive suppliers’ diverse parts requirements for fenders, bumper panels, hoods, tailgates, fuel doors, and side mirrors.

At the same time, LG Chem is using CNT, a filler that produces excellent conductivity even with a small amount in its engineering plastics to support diverse requirements of customers. Since this material can cover a wider range of electrical conductivity compared to other carbon fillers such as Carbon Black and Carbon Fiber, it is considered an optimal solution for powder coating. LG Chem has not only built its own CNT production line, but now expanding its 4th plant for a mass production in 2024, for the reliable supply of high-quality products for powder coating.